Client: Rapid Robotics

Category: Industrial Robotics

2022-2023 | Card79

Red Dot Award | Product Design | Winner

BOLD Awards IV | BOLDest Robotics | Finalist

Muse Design Award | Product Design | Platinum Winner

Building a complex system designed to scale to any workshop.

Rapid Robotics is lowering the barrier for smaller US based manufacturers to begin leveraging robotics to bring advanced manufacturing capabilities back on shore. What makes their robots unique is the ease with which they can be deployed and adapted quickly for different production requirements. Shipping adjustments quickly and getting real-time feedback from users was crucial to the success of this agile platform.

THE BRIEF

We collaborated closely with Rapid’s New Product Introduction team to create an industrial grade version of their existing lower power collaborative robot platform. The Industrial Robot Machine Operator (IRMO) ‘s goal is to provide flexibility and simplicity of setup, while providing power and speed to accomplish more heavy duty tasks.

MY ROLE

Industrial design | Physical prototyping | Surface design | Design for manufacturing | Vendor management

PROCESS

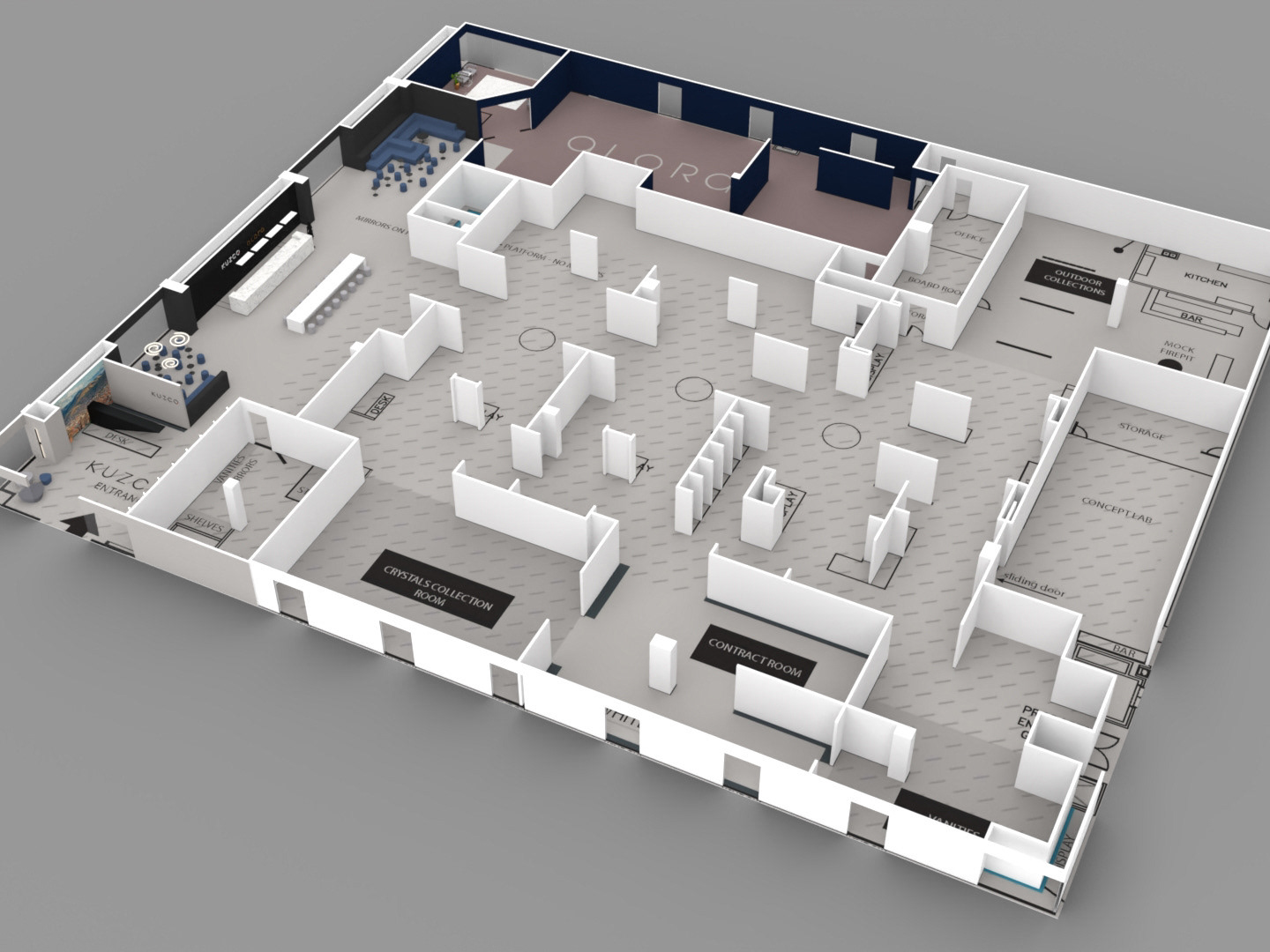

Because of the many possible robot and cell configurations, we began the design process by carrying out a thorough audit of all the different types of manufacturing cell shapes, sizes and equipment that we thought most cells would be composed of. The initial intent was to design reconfigurable and mobile fencing solutions.

Pivoting Focus

After evaluating the various cell types and the ROI of developing custom fencing, we opted to use off-the-shelf fencing and instead focused our creative energies on creating custom pedestals for the robotic arm as well as custom control boxes for the robot’s drive electronics.

Portability

As we developed the pedestal and control box, we found ourselves iterating on ways to enable portability, primarily looking at well designed handles and hooks.

Versatility

The robotic plinth was designed to have as small a foot print as possible in order to allow it to get as close as possible to different sized manufacturing equipment. The pedestal base was also designed to mount multiple table tops in different locations to accommodated different manufacturing fixtures and processes.

Outcome

We delivered a first unit to Rapid Robotics. Initial feedback has been very positive with plans to deploy all future collaborative and industrial robots using our proposed design.